| Home |

| Services |

| Forms |

| FAQ's |

| Clients |

| Links |

| Private |

| Contact Us |

| Nicholson Petroleum Maintenance, Inc. 798 Lighthouse Ave #193, Monterey, CA 93940 Phone: 831-905-5744 Fax: 831-583-0698 Email: npminc@sbcglobal.net

FAQ's

|

2. Do you know when your last pressure decay test was?

3. Do you know when your last tank monitor recertification was?

4. Do you know when your last spill bucket test was?

5. Do you know when your last secondary containment test was?

6. Do you meet Phase I or Phase II Vapor Recovery requirements?

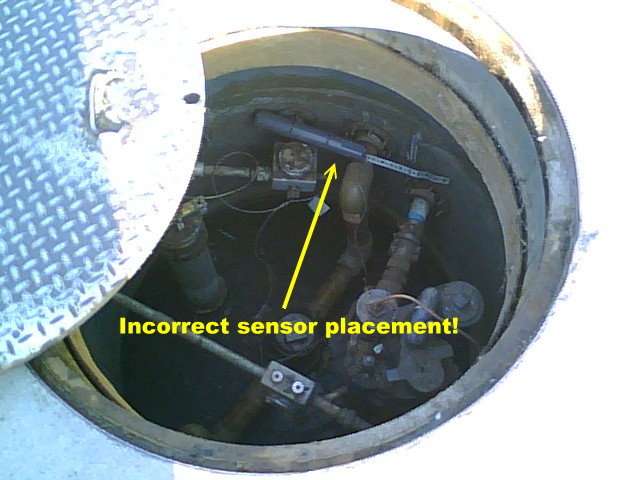

Why do we do inspections? The following two pictures say it all. This was found at a routine stop during the monthly inspection. I guarantee an official would love to site this infraction! Notice the water in the piping sump.

1. Effective January 1, 2005, you must have a Designated UST Operator to do monthly inspections on your site, and train facility employees. CR Title 23 2715(a-c)(f)

2. A pressure decay test and/or other air board tests, must be done annually by a licensed/trained technician. Your local Air Board has jurisdiction over these tests. Check your permit date or contact your local board to know when your tests are due.

3. Your storage tank monitoring equipment must be inspected and/or calibrated every 12 months. This must be done by a qualified service technician, and, be trained and certified by the manufacturer of the equipment. CR Title 23 2638. These records must be kept on site for 3 years. CR Title 23 2612

4. Spill buckets must be tested every 12 months. This is also included in the SB989 test (which is done every 36 months, see chart )

5. Secondary containment systems installed on or after January 1, 2001 shall be tested upon installation, 6 months after installation, and every 36 months thereafter. Secondary containment systems installed prior to January 1, 2001 shall be tested by January 1, 2003 and every 36 months thereafter. CR Title 23 2637(a)( see chart )

Recurrent Testing Chart

| Frequency | Prior Notice | Result Submitted |

| Sytstem | Test | Initial | Recurrent | When | Whom | When | Whom |

| Secondary Containment | Test | Install & at 6 months | 36 months | 48 hours | Local Agency | Within 30 days | Local Agency |

| Monitoring Equipment | Monitor Certification | Install & at 6 months | 12 months | 48 hours | Local Agency | Within 30 days | Local Agency |

| *Enhanced Leak Detection | Test | Within 18 months | 36 months | 48 hours | Local Agency | Within 30 days | Local Agency & SWRCB |

| Cathodic Protection | Test | Within 6 months | 36 months | ||||

| Impressed Current Cathodic | Inspect | N/A | 60 days | ||||

| Spill Buckets | Test | Install | 12 months |

6.

| What is Phase I and Phase II Vapor Recovery? |

| California Environmental Protection Agency Air Resources BoardVapor Recovery Advisory |

Gasoline Dispensing Facility Enhanced Vapor RecoveryImplementation Update |

The Enhanced Vapor Recovery (EVR) regulations became state law on April 1, 2001 with recent amendments adopted on July 22, 2004 (effective August 12, 2004). This advisory pertains to current and future EVR requirements for Phase I and Phase II vapor recovery systems at gasoline dispensing facilities (GDFs) with underground storage tanks. This advisory supercedes Advisory 321 issued on October 29, 2003.

The July 22, 2004, amendments affect the requirement for unihose dispensers as described on page three of this advisory. Modifications to the Phase II EVR implementation dates for new installations have been delayed by Executive Order G-70-205. Additional amendments to the EVR schedule, including a possible extension to the April 1, 2005 deadline for Onboard Refueling Vapor Recovery (ORVR) compatibility, are scheduled to be heard at the November 18, 2004, meeting of the Air Resources Board (ARB). For more information on future regulatory actions, visit the ARB vapor recovery webpage at www.arb.ca.gov/vapor/regulatory.htm

EVR DEADLINES DEPEND ON GDF CLASSIFICATION AS "NEW" OR "EXISTING"

The EVR program is being phased-in, according to the attached EVR timeline. EVR requirements apply to both new and existing vapor recovery system installations. New installations must comply with all EVR requirements in effect at time of installation. State law provides four years after the effective date of the EVR requirement for existing systems to comply. However, changes to the GDF that qualify as a "major modification" will change the status of an "existing installation" to a "new installation" and, thus, may require immediate upgrades to meet EVR requirements in effect at the time of the modification. This includes voluntary GDF upgrades or changes prompted by requirements of other agencies, such as the local water quality agency, except where specifically exempted from the "major modification" definition.

I. Modifications that Trigger EVR Phase I Requirements:

· Modification that causes the tank top to be unburied, including replacement or removal of an underground storage tank.

II. Modifications that Trigger EVR Phase II Requirements (including unihose dispensers):

· Addition, replacement, or removal of 50 percent or more of the buried vapor piping.

· The replacement of dispensers.

· Modifications to dispensers may require use of unihose configurations as described in CP-201 section 4.11.

Exceptions:

· The replacement of a dispenser is not a major modification when the replacement is due to an accident or vandalism.

· Phase II upgrades to make a system ORVR compatible do not constitute a major modification.

· Phase II system upgrades to comply with the under-dispenser containment requirement (CCR, Title 23, section 2636(h)(1)) initiated before January 1, 2004, do not constitute a major modification.

· The EVR program requirements are discussed in the following several sections.

PHASE I VAPOR RECOVERY SYSTEMS

Phase I system components reduce emissions associated with gasoline deliveries to the underground tank. All new GDFs, or those undergoing Phase I major modifications, constructed after July 1, 2001, must comply with EVR Phase I requirements. Existing facilities must upgrade to meet the EVR Phase I requirements by April 1, 2005. Information on certified EVR Phase I Vapor Recovery Systems can be found at http://www.arb.ca.gov/vapor/eo-evrphaseI.htm This webpage is updated as new EVR Phase I systems are certified.

EVR certified Phase I parts or components must be used as replacement parts when they are compatible with systems certified prior to EVR. EVR does not require use of parts or components when ARB has determined that they are not commercially available or if they are not compatible with pre-EVR Phase I systems. Installation of replacement components or parts does not require that the entire facility upgrade to a Phase I EVR certified system, unless the equipment replacement is part of a Phase I major modification.

LIQUID RETENTION NOZZLE REQUIREMENT

Effective July 1, 2001, vapor recovery nozzles at new gasoline dispensing facility installations must comply with the liquid retention requirement of 350 milliliters (ml) per 1,000 gallons of gasoline dispensed. Liquid retention is defined as gasoline in the atmospheric side of the vapor check valve and/or in the nozzle liquid path. Nozzles complying with the liquid retention standard are listed in Exhibit 1 of the latest version of Executive Order G-70-199 located at http://www.arb.ca.gov/vapor/eo-PhaseII.htm

Exhibit 2 of the latest version of Executive Order G-70-199 series lists replacement nozzles for existing certified Phase II vapor recovery systems. For systems without any nozzles meeting the liquid retention standard, non-compliant nozzles may continue to be sold as replacement parts only until April 1, 2005. Nozzles that are already installed on a system may be repaired with certified parts offered by manufacturers until the nozzle is replaced. All facilities must use nozzles that comply with the 350 ml liquid retention standard by April 1, 2005.

UNIHOSE DISPENSERS

The amendments effective August 12, 2004, will reduce costs to stations with non-unihose dispensers that are upgrading Phase II systems to meet ORVR compatibility requirements. Before the amendments, modifications to more than 50 percent of the vapor piping in a dispenser would trigger a unihose dispenser conversion. Under the recent amendments, facilities with non-unihose dispensers installed before April 1, 2003, are not required to change to unihose dispensers unless:

1. The facility replaces more than 50 percent of the dispensers.

2. Facility modifications occur that meet the definition of "major modification" for a Phase II system.

Exception: Dispensers which must be replaced due to damage resulting from an accident or vandalism may be replaced with the previously installed type of dispenser.

ORVR COMPATIBILITY

Phase II vapor recovery systems installed after April 1, 2003, must be compatible with Onboard Refueling Vapor Recovery (ORVR) systems. ORVR systems were introduced in 1998 model vehicles and now are required on most new cars and light-duty trucks. Phase II systems currently certified as ORVR compatible are provided below.

| Phase II System | CARB ExecutiveOrder & Approval Letters | Method of Achieving ORVRCompatibility |

| Healy | G-70-186 G-70-191 |

Nozzle senses ORVR vehicles and turns off assist vapor pump |

| Balance | G-70-52 Letter 03-04 |

No vapor pump, so no forced air ingestion into underground tank |

| Hirt | G-70-177-AA Letter 03-06 |

Vapor processor maintains negative pressure. |

Under existing regulation, existing facilities must have ORVR compatible Phase II systems by April 1, 2005. ARB will consider an extension to the ORVR compatibility April 1, 2005, deadline at the November 18, 2004, Board meeting. Comments are welcomed on the staff's proposal to be released on October 1, 2004. Please visit www.arb.ca.gov/vapor/regulatory.htm for more information.

EVR PHASE II (INCLUDING EVR NOZZLES AND IN-STATION DIAGNOSTICS)

Phase II vapor recovery systems control emissions associated with vehicle fueling. EVR Phase II systems are certified to several new standards, including ORVR compatibility, more stringent spillage and "dripless nozzle" requirements, in-station diagnostics (ISD), and storage tank pressure limits. Several manufacturers have submitted applications for EVR Phase II certification, but no system has yet been certified. By regulation and ARB Executive Officer action (Executive Order G-70-205), the implementation date for the new EVR Phase II system standards, other than ORVR compatibility and ISD, has been delayed to January 1, 2005. The implementation date for EVR Phase II systems with ISD is now April 1, 2005. At present, existing facilities have until April 2009 to upgrade to EVR Phase II systems.

Two systems are currently approved for use in California. See this page for information on which system will best suit your stations needs.

ISD PHASE-IN AND EXEMPTION FOR LOW THROUGHPUT FACILITIES

ISD systems will be certified in conjunction with EVR Phase II systems and will alert the station operator when a vapor recovery system failure occurs and will shut down dispensing if the problem is not addressed. Deadlines for ISD installation depend on the facility gasoline throughput as shown in the following table, which reflect recent extensions approved by the ARB Executive Officer. An extension to the ISD deadlines for stations with throughputs greater than 600,000 and less than 1.8 million gallons per year will be considered as part of the November 2004 rulemaking.

| Gasoline Annual Throughput(gal/yr) | ISD Required forNew/Modified* Facilities | ISD Required forExisting Facilities |

| > 1.8 million | April 2005 | April 2009 |

| > 600,000 and < 1.8 million | April 2005 | April 2009 |

| < 600,000 | NOT REQUIRED | NOT REQUIRED |

AIR POLLUTION CONTROL DISTRICTS/AIR QUALITY MANAGEMENT DISTRICTS

Although the State Air Resources Board sets vapor recovery system standards and is responsible for certifying systems to meet those standards, districts have primary authority for regulating GDFs under vapor recovery rules. Districts also issue GDF permits and conduct compliance inspections and testing. GDF operators should contact the local air district for specific information on local vapor recovery requirements before modifying the facility.

PARTIAL EVR EXEMPTION FOR OZONE ATTAINMENT DISTRICTS

Existing GDFs in districts that are in attainment with the state ozone standard are exempt from most EVR requirements and may continue to use pre-EVR systems. These facilities are still subject to the deadline for ORVR compatibility. Also, new GDFs and existing GDFs undergoing a major modification in attainment areas must comply with the applicable EVR requirements.

FOR MORE INFORMATION

Answers to frequently asked questions on the vapor recovery requirements are available at http://www.arb.ca.gov/vapor/faq.htm You can also submit a question at this website. Answers to the most common questions will be posted.

Information on the Vapor Recovery program is available at the Air Resources Board vapor recovery web site at http://www.arb.ca.gov/vapor/vapor.htm or by contacting the ARB Engineering and Certification Branch at (916) 327-0900. Information on the State Water Resources Control Board's California Underground Storage Tank program can be found at www.swrcb.ca.gov/cwphome/ust/

The energy challenge facing California is real. Every Californian needs to take immediate action to reduce energy consumption. For a list of simple ways you can reduce demand and cut your energy cost, see our web site at www.arb.ca.gov

7.

Stage II vapor recovery is an effective control technology to reduce the gasoline vapor emissions from volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). The stage II vapor recovery system used at a gas station is the gasoline dispenser. The components on that dispenser collect the vapors displaced into the atmosphere from refueling an automobile at the vehicle's fill pipe and return them to the underground storage tank.

The California Air Resources Board (C.A.R.B.) approves or disapproves vapor recovery systems used at gasoline dispensing facilities. C.A.R.B. will issue an Executive Order (E.O.) number, which governs the configuration of a vapor recovery system. The E.O. will refer to specific testing requirements for that system.

The equipment and the system used to recover the VOCs and HAPs must be periodically checked by service personnel to insure that it is functioning properly. NPM, Inc. offers services to assist an underground storage tank owner in complying with the requirements of their state's environmental office for periodic testing.

As an underground storage tank owner, you will also need to provide documentation to state regulators that you are visually inspecting and maintaining the stage II system components on a regular basis to ensure that there is not damage to the system components.

For links to your state air quality division click here.

|

Talk about EPA Requirements |  |

The EPA has mandated that Underground Storage Tank (UST) owners meet the following guidelines:

Spill Prevention - Spill prevention can be obtained by using a catchment basin attached to the fill pipe of each tank.

Overfill Protection - Overfill protection can be obtained by using one of the following for each tank: Automatic Shut Off Device, Overfill Alarm, and Ball Float Valve.

Corrosion Protection - All underground steel tanks and piping routinely containing product must be protected from corrosion. This can be accomplished by using non-corrosive materials or by installing impressed or sacrificial cathodic protection systems to steel tanks, steel lines, steel swing joints, and steel flex connectors.

Leak Detection - In general, most tanks and lines must have some form of leak detection. This can be accomplished by using one of the following: Automatic Tank Gauging, Vapor Monitoring, Secondary Containment with Interstitial Monitoring, Groundwater Monitoring, Statistical Inventory Reconciliation (SIR), or any other method approved by the regulatory authorities.

Financial responsibility - As a UST owner you must be able to demonstrate your ability to pay for damages that could occur if your UST leaks.

Visit the EPA Office of Underground Storage Tanks website for more information.

You may also have specific state/local guidelines that need to be met. NPM, Inc., or a representative within your state environmental office, can discuss with you in further detail how the regulations will affect you. Here is the regulatory link for your convenience - California Underground Storage Tank Program .